13:30 PRINTABLE HEADPHONES

13:30 PRINTABLE HEADPHONES

13:30 is a thought piece exploring 3D printing as an end product delivery service. The name represents the time it takes to create a pair of these headphones; 13 hours to print, 30 Minutes to assemble (give or take). My end goal was to create an easy to print, easy to build, fully functional pair of headphones.

This 3D printed focus manifests itself in a few ways on this design. For the main assembly I used the plastics natural elasticity, designing purposeful flex points to deliver comfort and adjustability without the use of mechanical joints. The ear pads also had to be rethought from the standpoint of something that would be comfortable but easy for the end user to make. Here I went with a simplified 'stretched fabric in frame' instead of the more complex multi material approach used in contemporary headphones. I have provided the core 3D printed files free to everyone at Thingiverse.com as well as build instructions and sources for where to pick up the parts that can't be printed (e.g. speaker drivers, connectors and cables).

13:30 PACKAGING

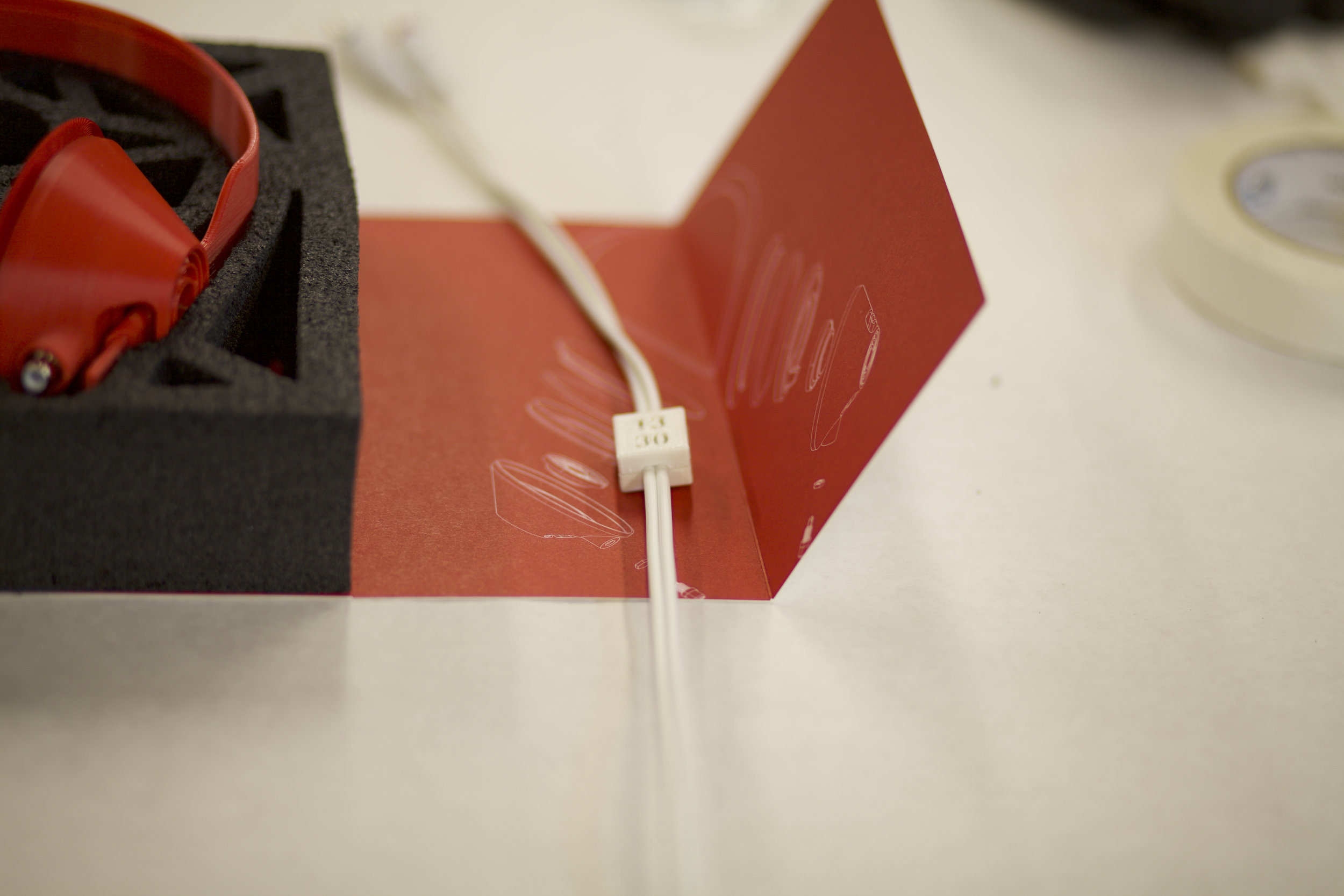

To answer repeated requests for samples for the 13:30, I designed and created packaging for about a dozen 13:30 headphones samples that TEAGUE would send out to a small list of gadget blog partners and professional friends.

It was a bit odd for me to do this as the whole point of the project was for the individual to make their own headphones with individual desktop manufacturing. In this case I would be using our house 3D printer to create multiple production copies and pre assemble and test these copies them for the sake of marketing. To me, its still a strange request that totally misses the point and highlights the laziness of marketing in general. But I had a new design challenge, and I love design challenges!

The design was based on the same easy and economical to fabricate and build principle as the headphones themselves. The box structure is provided by water jet cut foam blocks bonded to and wrapped in custom card-stock prints. The outside of the box, aside from having the 13:30 name prominently displayed, also displayed the entire G-code the 3D printer used to create the headphones. on the inside was a series assembly illustration detailing how the headphones were put together.

Special Note:

Inside every pair of headphones we sent out, I also included a special thank you message inside the assemblies. This was a small reward for the curious souls that would take them apart to see how they were built. To this day I've never heard back on whether or not anyone discovered this, but I like to think maybe a few did.

FEATURED: